Livraison 24/48H - Départ Le Jour Même Avant 16H00 - France, Europe, Monde

552 products

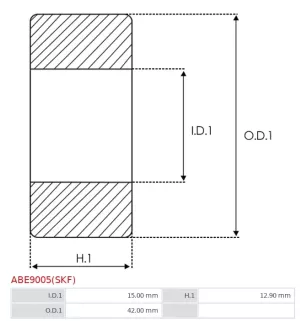

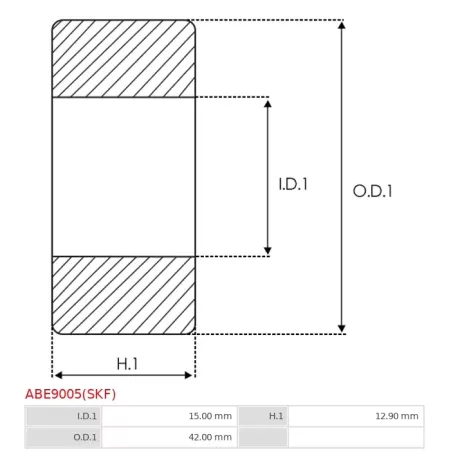

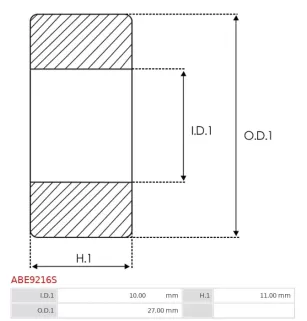

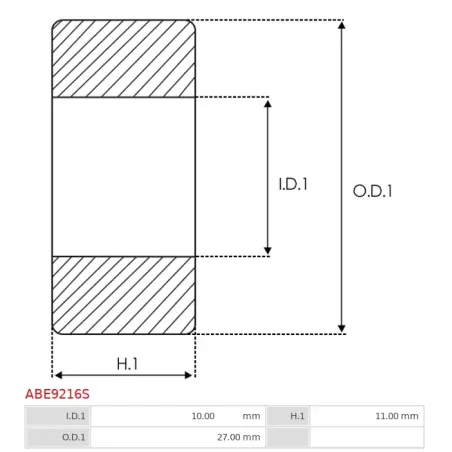

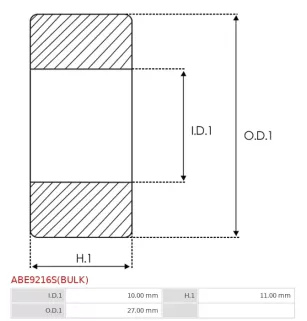

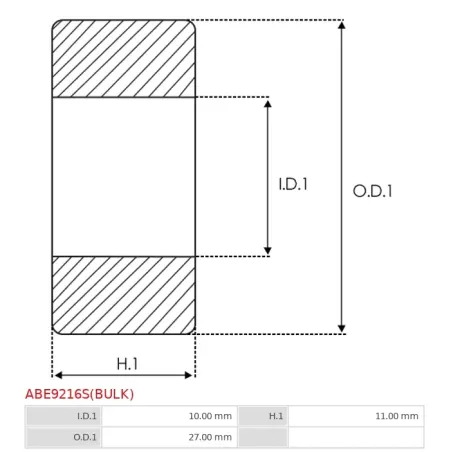

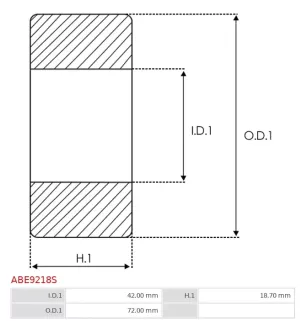

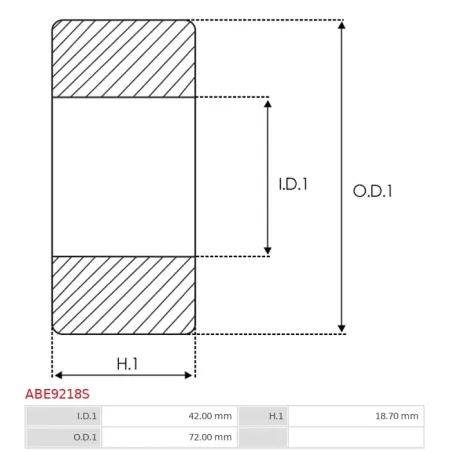

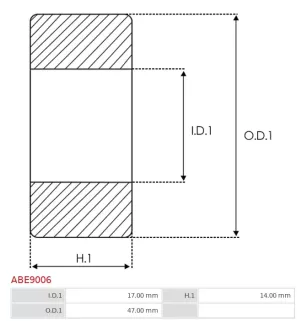

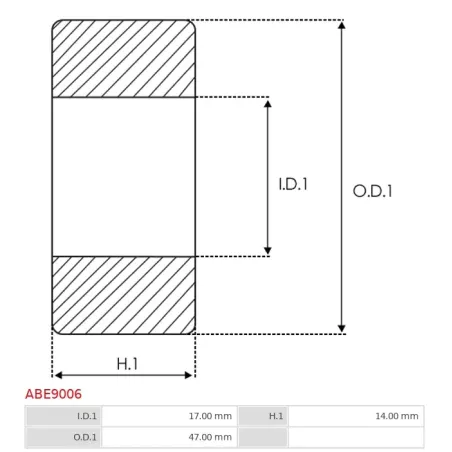

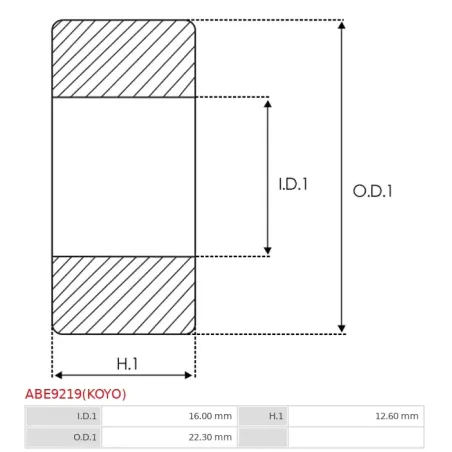

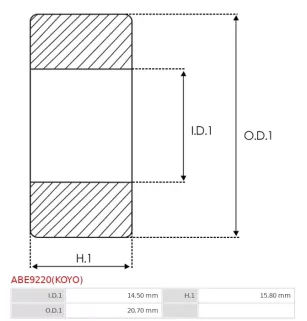

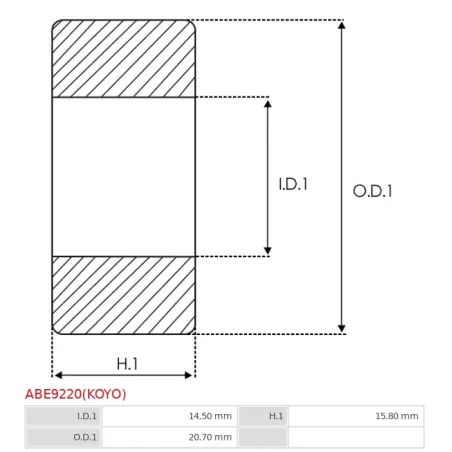

Palier AS-PL UD17284ABE(KOYO), KOYO DB-600-023, ELECTROLOG BEA600023

Alternator bearings

Alternator bearings:

Are important components in a vehicle alternator, which is a part of the car's electrical charging system. The alternator is responsible for generating the electricity needed to recharge the car battery and power the vehicle's various electrical components, such as headlights, air conditioning, radio, etc. ball or roller bearings which are used to support the alternator shaft and enable its rotary movement at high speed. They are located inside the alternator, and their proper operation is essential to ensure that the alternator is functioning properly. When alternator bearings begin to wear or show signs of failure, several problems can occur, including: 1. Noise: A grinding or clicking noise coming from the alternator area can indicate faulty bearings .

The term "alternator bearing" refers to the bearings used in alternators. An alternator is an electromechanical device that generates electricity by converting mechanical energy into electrical energy. It is often used in power generation systems, such as generators, cars and other electrical equipment.

Bearings are essential elements of alternators because they allow the rotor (rotating part of the alternator) to rotate smoothly. Bearings are components designed to reduce friction and support loads, allowing the rotor to spin with minimal resistance. The bearings used in alternators must be of high quality to ensure reliable operation and long life of the alternator.

The type of bearings used in an alternator can vary depending on its design and specific application.

Ball bearings are commonly used in many alternators because they provide low friction and high load capacity. Cylindrical and tapered roller bearings can also be used in certain applications, depending on design requirements.

It is important to maintain and replace alternator bearings regularly to avoid breakdowns and performance problems. Signs of bearing failure may include abnormal noises,excessive vibration and loss of electrical power. If you suspect bearing problems in an alternator, it is recommended that you have the unit inspected and repaired by a qualified professional.